We empower businesses to make the most of their data by offering them advanced tool chain consulting.

We set up scalable PySpark environments in Microsoft Azure, streamline data into Databricks, and transform it with Pandas/Spark DataFrames.

Get actionable insights fast – with custom interactive dashboards tailored to your business.

PROSPERING GROWTH

CUSTOMER CASE

-

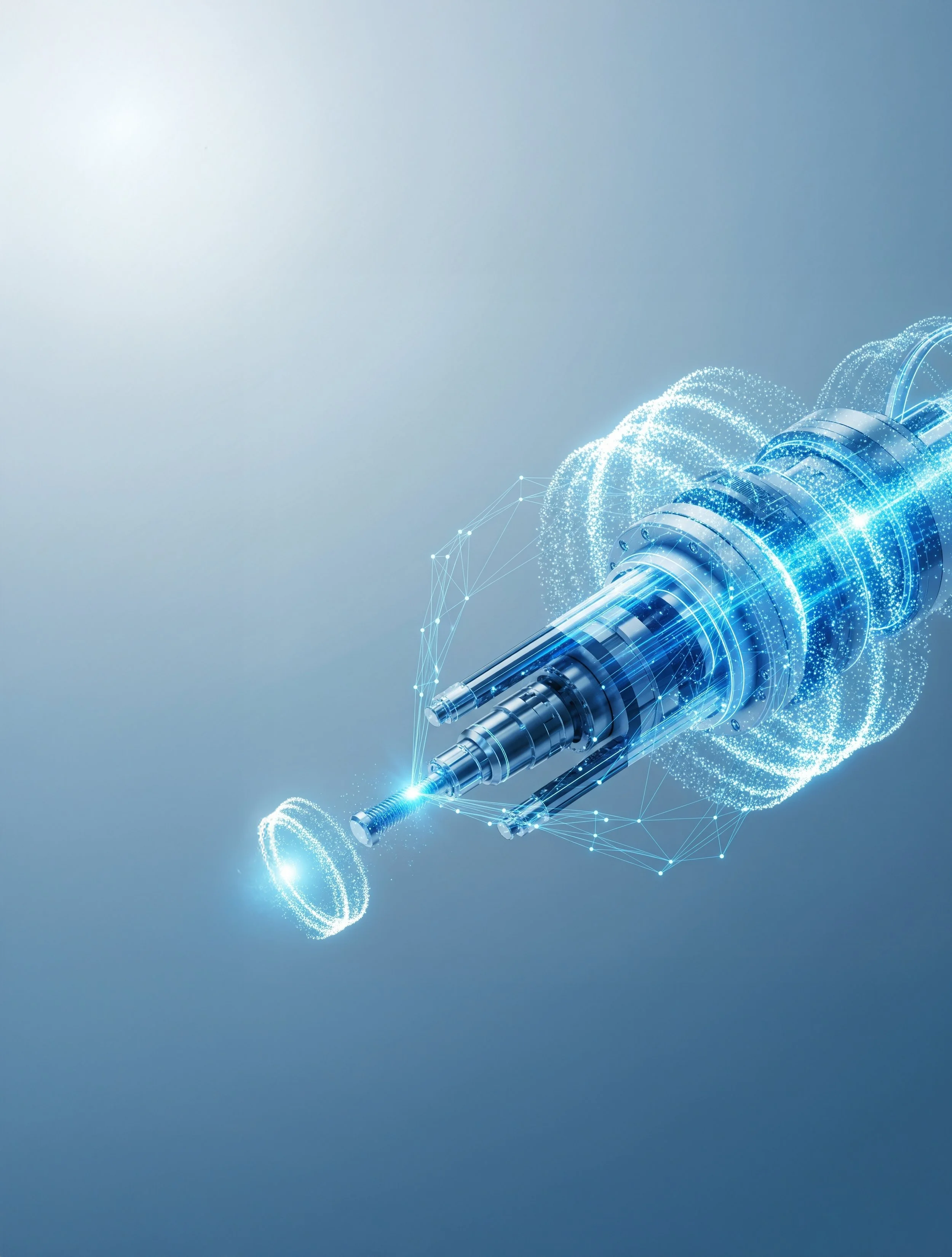

Vehicle Equipment Manufacturer facing random failures in a critical bolt installation machine. Unscheduled downtime on a key assembly line machine due to inconsistent bolt installation failures, leading to production delays and increased costs.

-

Sensor Data: Collected real-time data from the bolt machine's sensors (torque, pressure, vibration, temperature, cycle time).

Maintenance Logs: Gathered historical records of past failures, repair times, and parts replaced.

Production Data: Integrated production line data including batch numbers and operator shifts.

Cleaning: Addressed missing values, outliers, and normalized data for consistent analysis.

-

Utilized a secure Microsoft Azure environment for scalable data ingestion and storage.

Implemented robust encryption of data at rest and in transit for raw data analytics safety.

Applied identity and access management (IAM) with multi-factor authentication and RBAC to control access.

-

Developed interactive PowerBI dashboards to visualize machine performance metrics, failure trends, and sensor readings over time.

Created PowerPoint presentations with key findings for easy understanding across departments.

-

Identified specific sensor anomalies (e.g., sudden torque drops, atypical vibration patterns) preceding failures.

Correlated sensor data patterns with historical maintenance logs to diagnose specific component issues.

-

Built machine learning models to predict potential machine failures based on identified pre-failure signatures in sensor data.

Forecasted the likelihood of a bolt installation failure within a specific time frame, enabling proactive interventions.

-

Recommended optimal maintenance schedules and specific component replacements before predicted failures occurred.

Suggested ideal operating parameters to minimize wear and tear based on real-time conditions.

-

Alerts were automatically triggered for maintenance teams when a high-risk failure was predicted.

Maintenance tasks were shifted from reactive to proactive based on historical data, allowing scheduled downtimes with reduced impact on production.

-

Reduced unscheduled machine downtime by 40%, significantly increasing production uptime.

Decreased maintenance costs by 25% due to fewer emergency repairs and optimized part replacement.

Improved overall equipment effectiveness (OEE) by 15%, leading to higher throughput and reduced waste.

Optimizing Bolt Installation Machine Reliability

500000 EUR

ESTIMATED ANNUAL SAVINGS